Have you ever wondered which of Boiling Water Resistant (BWR) plywood and Moisture Resistant (MR) grade plywood is better? A lot of people have a muddy idea about BWR and MR grade plywood and you don’t need to be one of them.

SO WHICH ONE WILL YOU CHOOSE- BWR OR MR?

Boiling Water Resistant Plywood:

Boiling water resistant plywood, as the name suggests is waterproof and is ideal for applications that are frequently exposed to water. It is also of exterior grade quality, meaning it can also be used in the exteriors. BWR grade plywood is also weather-proof.

BWR grade plywood is ideal for making furniture used outside like

- lawn chairs

- garden tables

- chairs

- restaurant

- cafes

Most interior designers and decorators, these days, prescribe the use of BWR plywood for making kitchen cabinets and other furniture as these have a high probability of getting wet.

Also Read – The Role of High-Quality Plywood in Construction and Design

This type of plywood is generally glued using synthetic phenolic resins giving it its unique water-resistant property. I would also like to add that generally PHENOL FORMALDEHYDE adhesive is used in order to bind together the different layers and grains of ply.

BWR grade plywood is very strong and can resist warping even when exposed to water for long periods.

Since I have been talking about the water-proof properties of this grade, I need to clarify that BWR or BWF (boiling water proof) grade plywood should not be confused with the marine plywood.

It is of even better quality and is normally used for building boats and ships, which remain partially submerged under water for long periods of time and for big commercial projects.

Being of superior quality, it is naturally more expensive than BWR plywood. So for home or office furniture, keeping the cost constraints in mind, BWR or BWF grade plywood is generally preferred over marine grade.

Moisture Resistant Plywood:

Now let’s talk about MR(Moisture Resistant) grade plywood. It needs to be clearly understood that although this grade is moisture resistant, it is not resistant to water. So this type of plywood is not used to make furniture perennially exposed to water.

This is also commercial grade plywood which has a very high internal strength. It is used mainly in the interiors of a home or office.

It is suitable for making furniture like

- Kitchen Rooftops

- Wall Mounted Cabinets

- File Cabinets

- Doors

- Chairs

- Room Tables

Moisture resistant grade of plywood has the highest internal density among all the available grades of plywood.

That makes it robust and also resistant to warping or folding. This definitely increases the longevity of your furniture. MR plywood is also called interior-grade plywood.

Adhesive Used:

UREA FORMALDEHYDE adhesive is used for binding the different layers or grains of MR grade plywood. I would just like to point out that according to some environmental experts, phenol formaldehyde is more eco-friendly than urea formaldehyde.

Both BWR and MR grade plywood are supposed to conform to IS:303 specifications of the Indian Standard product or process quality set by the Bureau of Indian Standards (BIS).

Hopefully, now you have a fairly good idea about BWR and MR grade plywood. But this may not be enough for you. I am sure your mind is already wondering which are the best available brands in the two categories? The answer, however, is surprisingly simple.

Duroply’s Duromac:

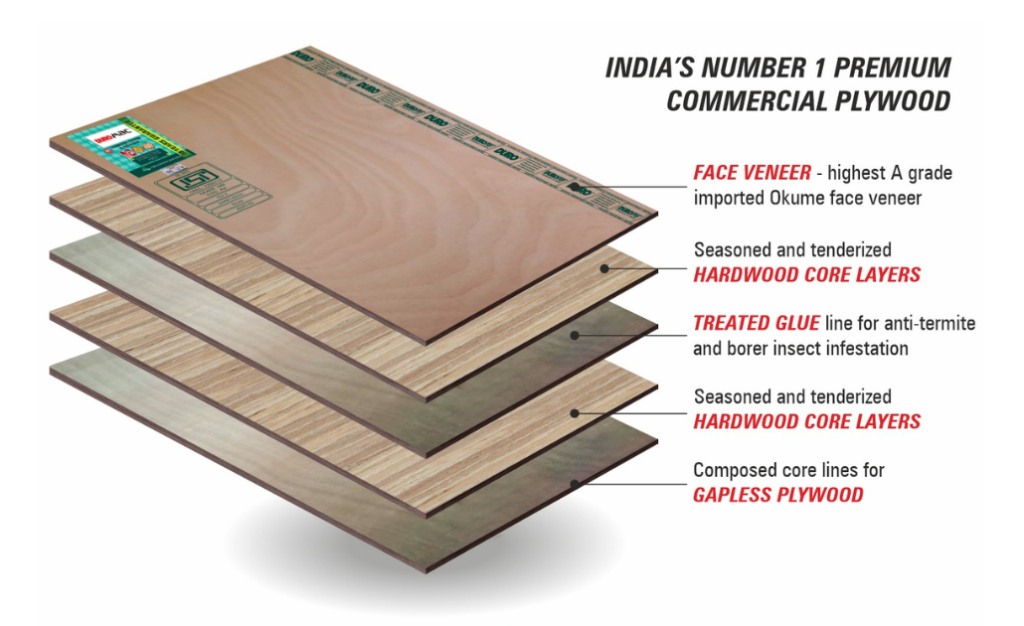

It is difficult to find a more reliable brand of plywood than Duroply’s Duromac if you are looking for any one of the BWR and MR grade plywood. This amazing product is the result of years of endeavor and cutting edge research. It is one of the most innovative products built to date by Durolpy using some of the most advanced techniques.

Duromac is 100% water resistant and made from selective matured wood and bonded with strong formaldehyde resins. Duromac is available in both the categories – BWR and MR.

There is a saying that you have to pay a higher price for anything that costs less. The price is low quality and a shortened life span. But in the age of rising inflation and recurring recession, we have used innovative techniques to create a product which ensures that you do not have to compromise on quality even when forced to manage costs. Duroply would never compromise on quality under any circumstance. You can rely on us.

Duromac Plywoods and Block Boards:

Duromac plywoods and block boards are also treated with a secret mix of chemicals and preservatives which create a powerful barrier around it that helps it to fight borers, termites, and other wood boring insects.

Duromac, owing to intensive quality checks, ensures a remarkable performance in terms of strength, homogeneity, smoothness and dimensional stability. It has a wide range of applications.

So, I would recommend that you should first identify your exact requirement before deciding which grade or quality of plywood you would need. Once that is done, even with blindfolds on, you can rely on Duromac.

Also Read – Modern Wardrobe Design Themes with Duro Veneers/Plywood

You can post your query or leave your valuable comment in the indicated box below. Your support is our inspiration which keeps us going. We would really appreciate it. I have just one small suggestion to make. Never compromise on quality. Go with the best because it would give you the highest ROI in the long run!